Finetech ensures information flows right on time: Aditech’s modern LCD Displays for transportation and industrial applications are manufactured on a FINEPLACER® system.

Every minute, thousands of people rush through train stations, looking for their track or confirmation that the train is on time. Although constant announcements blare through the PA, nearby construction work makes it nearly impossible to understand the message. That’s when huge electronic displays come in handy. Easy to read from afar, they list departure times and tracks, bringing order to the hustle and bustle and providing orientation and essential information at a glance.

One of the leading manufacturers of such passenger and traffic information systems is Aditech Flüssigkristallanzeigen GmbH from Heidenheim, Germany. LCD displays made in Heidenheim are used in train stations, in busses and trains, or as city and parking information systems all over Germany, Europe and around the world.

Process automation and customer-specific adaptation

Aditech began cooperating with Finetech in 1998, when they produced a line of sample displays for an automotive customer. For this chip-on-glass application, a manual FINEPLACER® pico was used. Soon after, this project was followed by similar orders, including Deutsche Bahn. Again, an initial line of samples provided very successful results. However, due to very strict requirements in terms of pixel density and the number of IC connections per display, an economic series production was only feasible on a fully-automated assembly system.

Aditech’s goal was to manufacture two full displays per hour. The required placement accuracy was rather challenging at 15 micron. Also, in order to cure the affixed driver chips, the system had to be able to handle UV curing. Finally, it had to be flexible so that new assembly technologies could be added at a later date.

Although Aditech had excellent results with the manual FINEPLACER® pico already in their lab, they did not associate Finetech with production equipment at that time. For them, Finetech represented prototypical micro assembly bonding systems for product development and research with a particular focus on accuracy and process variety. So Aditech was surprised when Finetech presented their first automated bonder during the SMT Hybrid Packaging Exhibition 2001 in Nuremberg. The machine offered a placement accuracy of 5 micron @ 3 Sigma and had exactly the degree of flexibility Aditech was looking for. This got their interest.

“Finetech has always been a very innovative and cooperative partner with us. They have been open to our requests and wishes. When required, they have been quick to come up with new technical solutions, and support has been nothing but straightforward.”

Co-Founder and CEO, Aditech

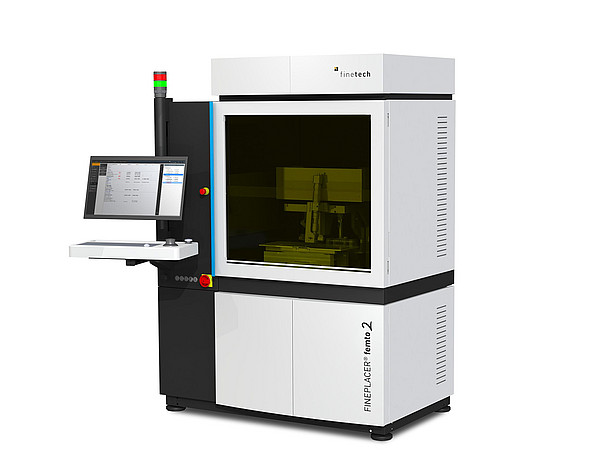

Over the following months, Aditech worked closely with the Finetech hardware and software engineers to customize the machine and adjust it to their application. For example, the optical system and pattern recognition software were modified to allow for a high-resolution recognition of fine structures over the whole length of large driver chips. Specific supports for large LCD panels were designed, too. As a result of these joint efforts, Aditech was able to begin series production on a fully-automated FINEPLACER® system at the end of the same year.

Fit for series production and new fields of business

Over the years, Aditech has expanded their machine park, which today includes six automated assembly systems by Finetech. During a typical production hour, around 150 ICs are reliably connected with ACP and then cured with UV. And remarkably, Aditech’s initial Finetech machine still meets all process specs and is used in full production mode.

Aditech has long found new fields of activity in addition to LCD information displays. Their business is evolving. The usual IC assembly for passenger information and traffic guidance systems is still a vital part, i.e. in Eastern Europe. In other markets, alternative applications are becoming increasingly important.

I.e., this includes industrial control displays, high-precision chip assembly on E-ink displays, or the retrofit of common LCD displays with additional illumination or protective glass. FINEPLACER® systems support all the new applications of Aditech and are also ready for further challenges.

„We have developed a very close and friendly partnership which continues to this day. Between 2001 and 2016, we successfully bonded around 13 million IC’s on FINEPLACER® systems. The result speaks for itself.”

Co-Founder and CEO, Aditech