Author: Dan Lilie

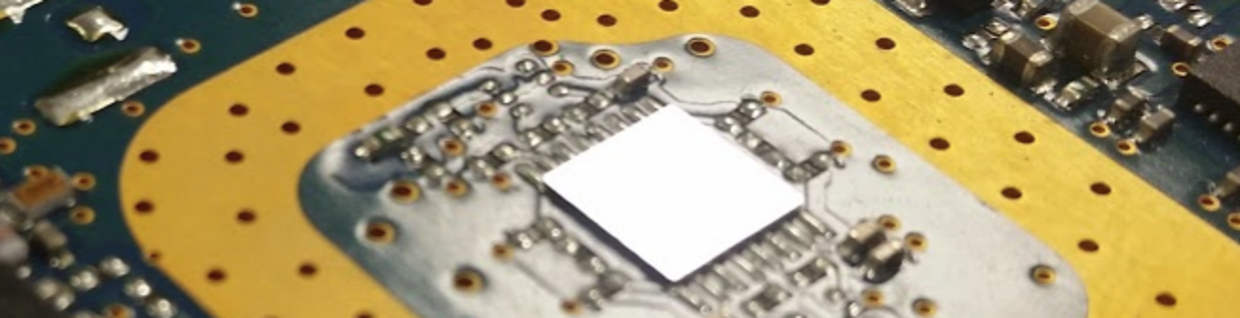

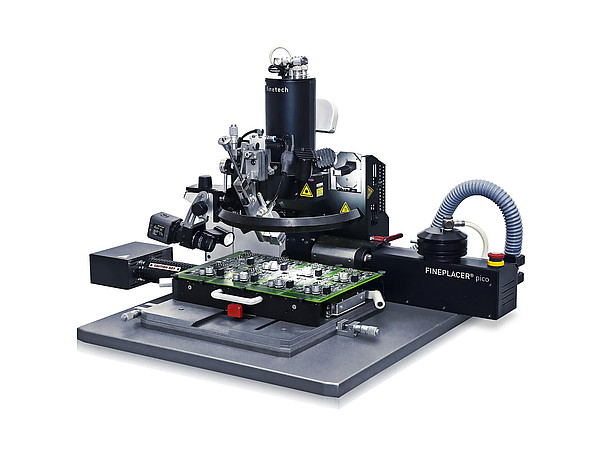

Abstract: Flip chip components have rarely been used in PCB assembly, but they are becoming more and more important as the need for miniaturization of electronic assemblies is growing. Flip chips are bare dies which are mounted directly, without any further connecting wires, onto the circuit carrier with the active side down. This means they come in particularly small sizes. This technology is often the only suitable assembly possibility for very complex circuits with several thousand contacts. Generally, flip chips are assembled by means of conductive bonding or pressure welding (thermocompression bonding), other options include soldering, ultrasonic bonding or diffusion bonding. This Technical Paper focuses on flip chip rework by means of soldering at PCB level.