From the first to the 2,000th board – Finetech ensures reproducible processes for high-volume BGA rework.

Even standard BGA rework can be challenging, especially when the goal is to have reproducible results. It is one thing to attain 100% quality – and it is another to sustain it over and over again with every repaired component.

BMK Group, a leading German EMS provider and a longtime partner of Finetech, offer services around the life cycle of electronic components, including development, production and repair. They are experts in chip-level rework and perform over 8,000 repairs per month for customers in various industries. For them, every chip matters.

Uncompromising rework excellence required

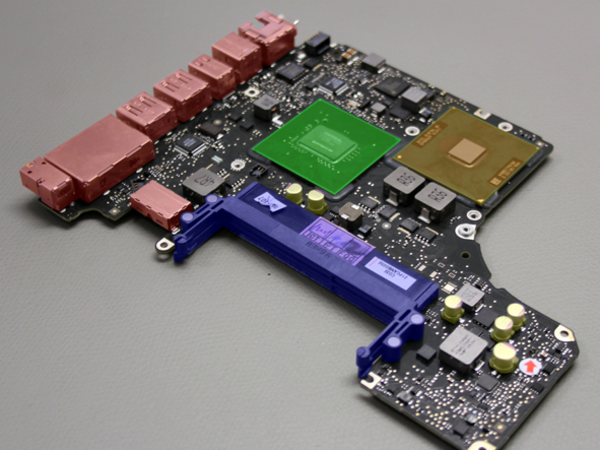

BMK received a request from a product manufacturer to repair 1,500 assemblies containing defective RAM components. The product was due to enter the market in 4 weeks. This put considerable pressure on BMK in terms of lead time, further increased by a possible contractual penalty for the customer, in their turn, if the company would not be able to fulfill their delivery obligations.

- multi-level CPUs with 8 layers each

- double-sided SMD population

- every module containing 8 or 16 RAM components, depending on the product line

Each RAM component had to be replaced individually, which meant 8x or 16x soldering and desoldering sequences for each module. In addition to the high thermal load, this would normally have resulted in a significant time expenditure for such large quantities.

The customer made their expectations very clear – nothing less than complete rework excellence. With these specifications, every component counts.

4 in 1

Such a demanding application needed a quick and reliable solution – and BMK and Finetech developed one together. Due to its process modularity, Finetech’s FINEPLACER® rework station allowed all process steps to be carried out within one system. Thus, the entire rework process was developed in a way that ensured stable reproducibility.

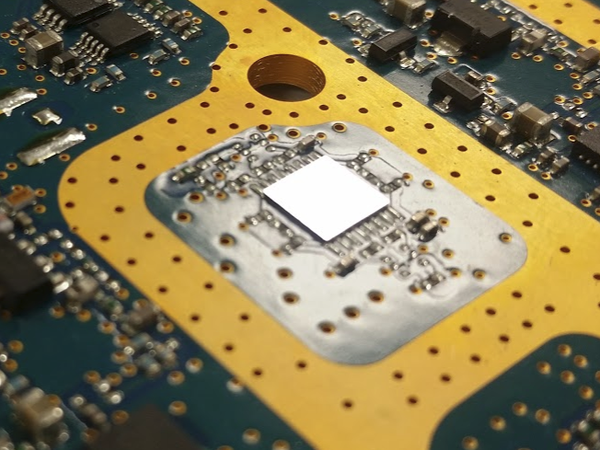

A customized soldering nozzle was designed specifically for the BMK application. It had four slots instead of one, where four RAM components could be desoldered at once. This way, four process steps could be cut down to one, which significantly reduced thermal stress and provided valuable lead time benefits not only for BMK, but also for their end-customer.

Quality without doubt

Due to very high output requirements, destructive tests were conducted to verify compliance with all customer specifications. The results showed the yield rate achieved on Finetech’s equipment was better than 99%, dispelling any doubts BMK and its customer might have had.

Later on, BMK received further requests from other manufacturers with very high requirements typical for the B2B sector and could always provide outstanding rework quality.

“We have been partners with Finetech for over 20 years now and they have always been open to our needs. The support they provide is immeasurable – their engineering team is very accessible and everyone is well connected and deeply involved with each project. The quality we get is always at the highest level – from the first to the 2,000th board.”

CEO, BMK Electronic Services