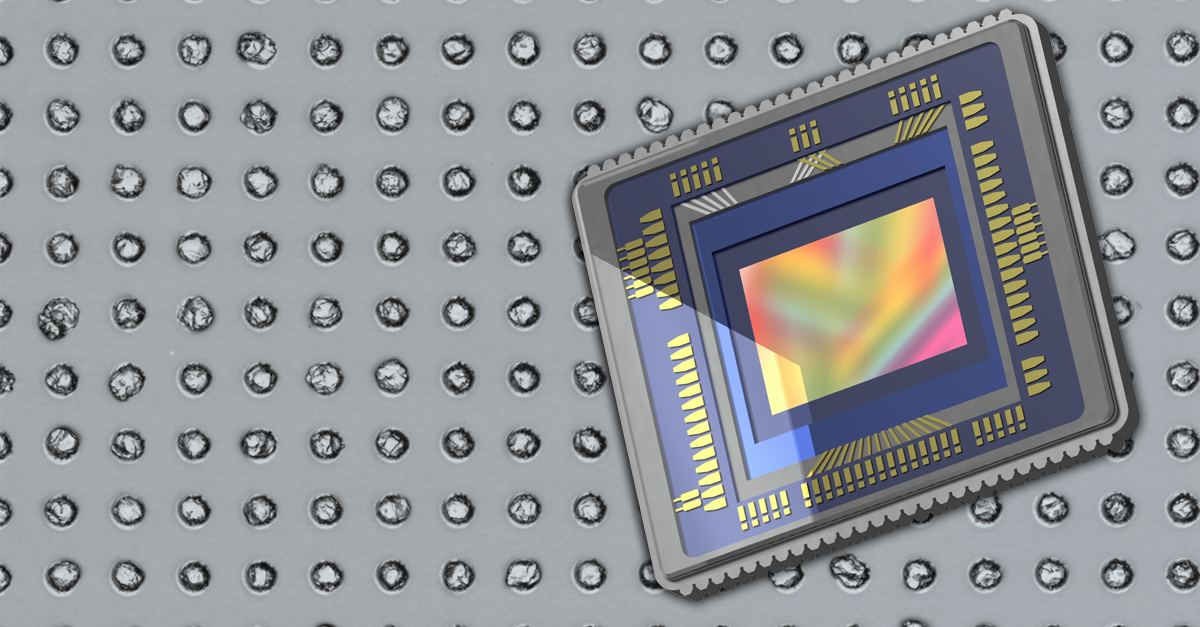

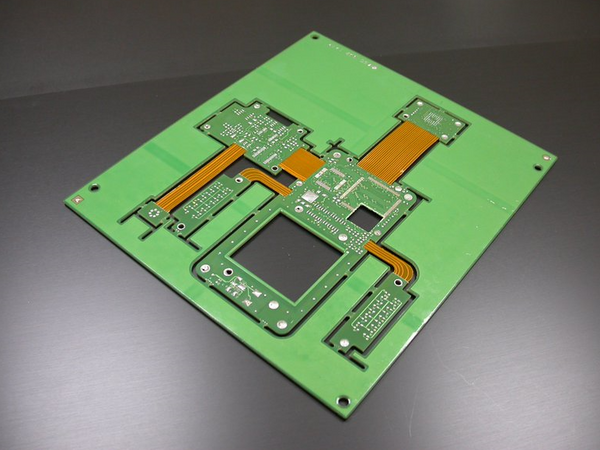

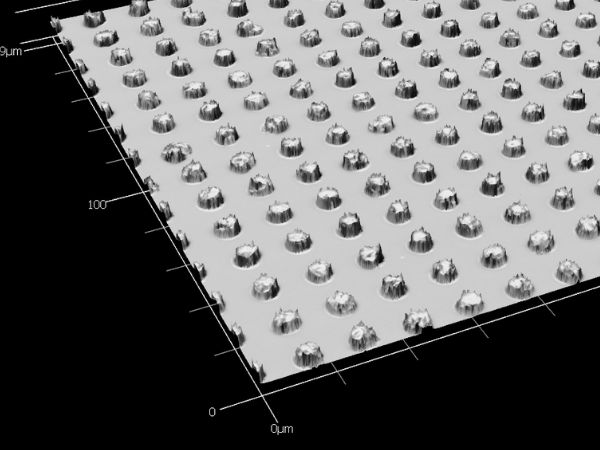

Indium Bump Interconnect (IBI) Flip Chip Bonding

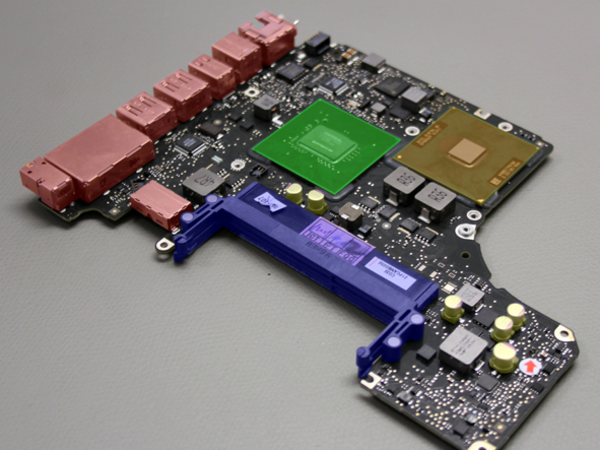

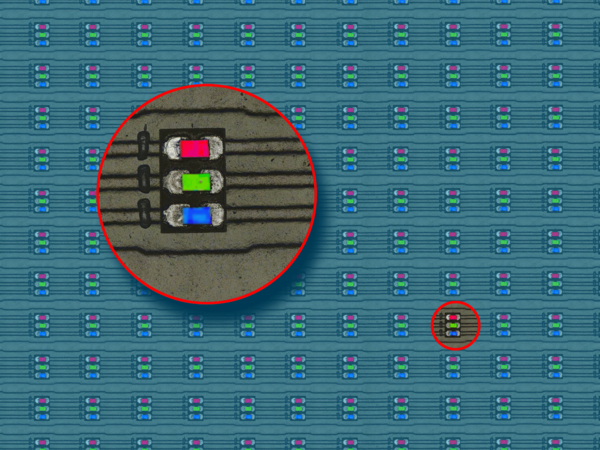

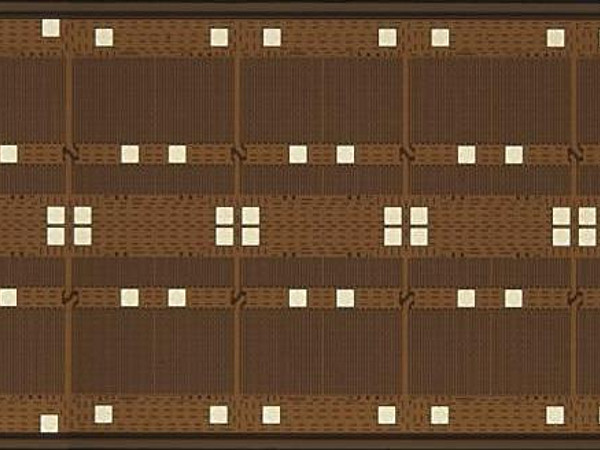

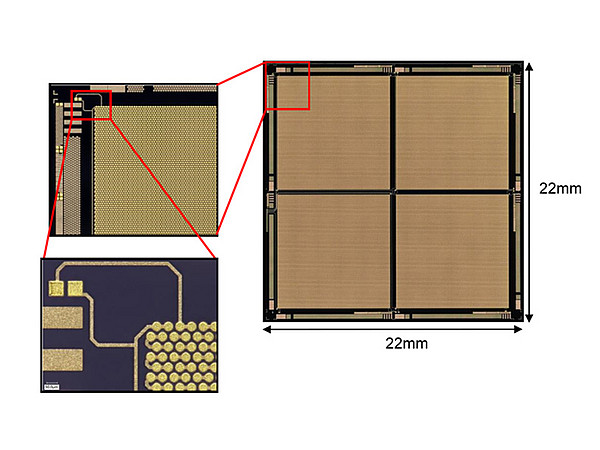

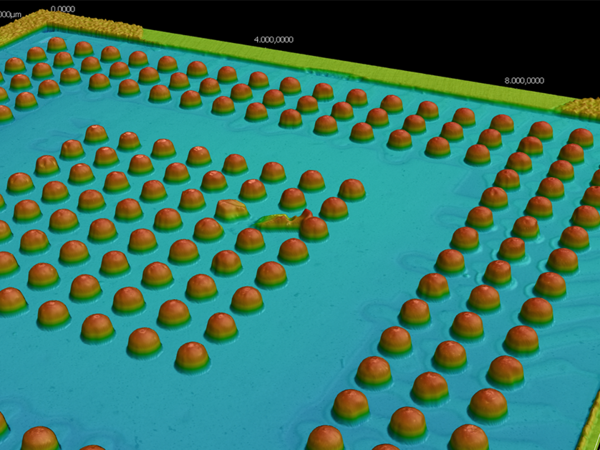

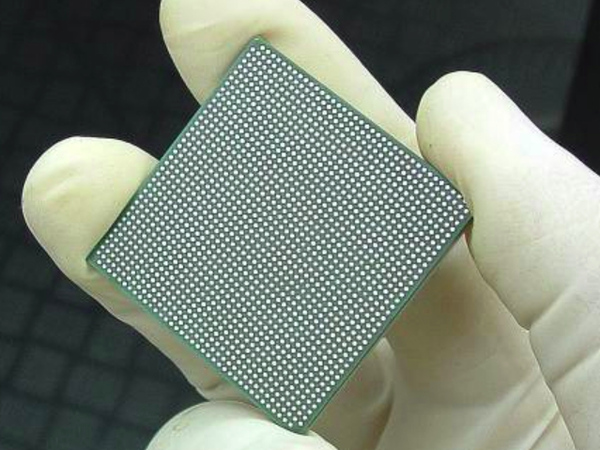

Higher pixel / Qubit count and interconnect density on larger and larger chips is driving hybridization and monolithic integration. This results in increased demand for fine pitch micro Indium Bump Interconnect (IBI) flip chip die bonding solutions.