Siemens AG in Fürth, Germany, successfully uses the hot air rework system FINEPLACER® coreplus for rework tasks in the production of electronics for industrial applications.

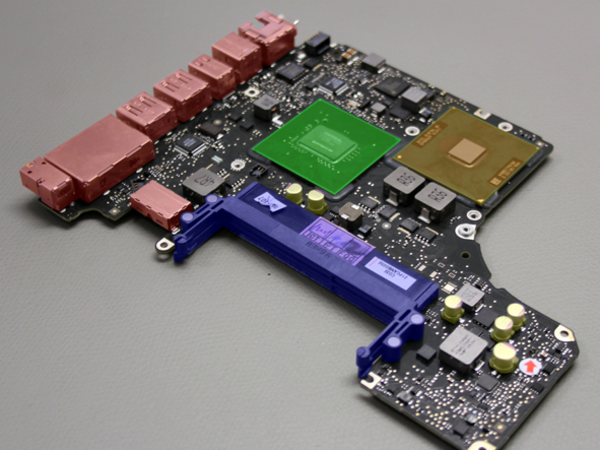

Around the globe, Siemens locations rely on Finetech systems for rework of electronic components and high-accuracy semiconductor assembly. One of them is the long-established production site in Fürth Hardhöhe, Germany. For decades, this Siemens facility has been producing electronic components, standardized and customer-specific modules and complete systems for industrial use, i.e. control and automation technology, as well as medical and energy technology.

The wide spectrum of different electronics manufactured in Fürth is unique in the realm of Siemens. It requires highly versatile production facilities, and also a very flexible approach to reworking manufacturing-related error cases at the production environment level. Not least, the rework results have to be extremely reliable, as Siemens offers its industrial customers a warranty of up to 25 years on electronic components.

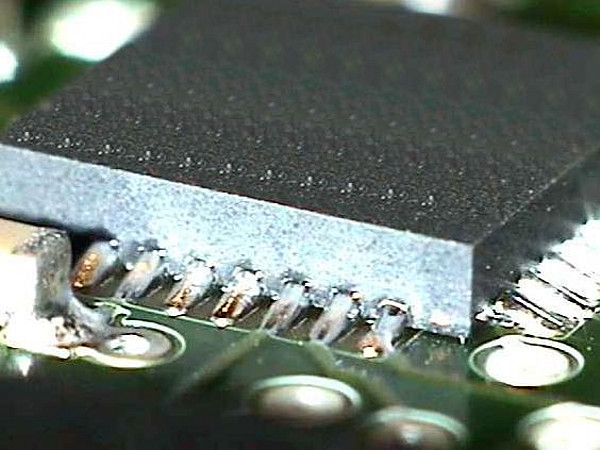

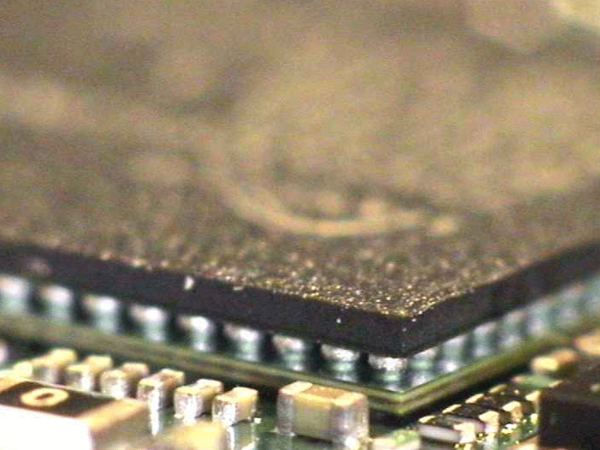

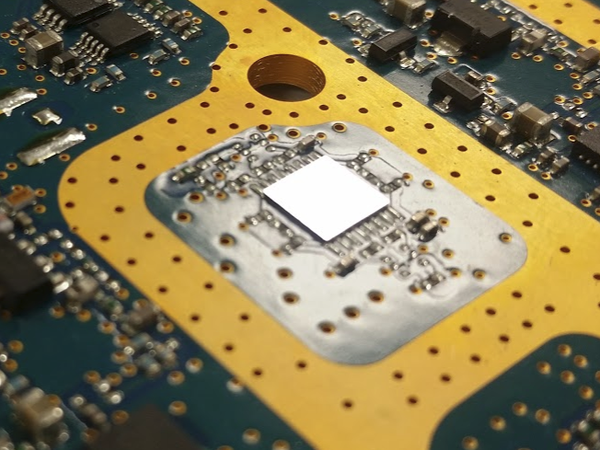

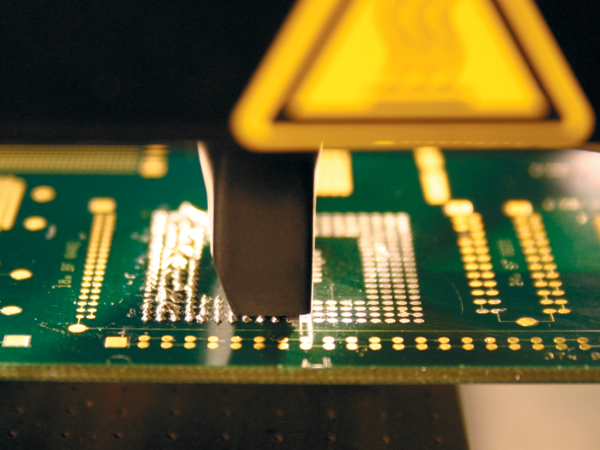

However, reworking very small components and assemblies on densely populated printed circuit boards is particularly demanding. The infrared heating technology previously used by Siemens had reached its limits with regard to optimum heat distribution, so Siemens was looking for a partner that could offer a state-of-the-art solution.

Wanted: Manual system for all applications

For the evaluation of suitable SMD rework systems in the market, the requirement was determined that the machine had to incorporate the complete rework cycle for a variety of applications – ranging from standard BGA to QFN to very small, fine pitch applications. Mr. Jörg Bernreuther and his production department team were also looking for a rework system that allows manual intervention to be able to make flexible adjustments to the varied individual rework jobs and to guarantee successful repair results the first time around.

Mr. Bernreuther, who has been following the trends and innovations in SMD production and rework since the early 90’s, was impressed by the Finetech system’s flexibility, straightforward functionality, and easy to handle contactless residual solder removal. Until then, this work step had to be done manually.

Found: FINEPLACER® core plus

Convinced by the results of the evaluation, Mr. Bernreuther and his colleagues decided on the hot gas rework system FINEPLACER® coreplus. Since 2017, thousands of rework jobs have been successfully performed on the machine.

Typical trends in electronics production — increasing miniaturization or the growing number of high I/O count components and highly integrated circuits — do not stop with electronics production for industrial applications and lead to constantly increasing requirements. The FINEPLACER® coreplus is proven to be optimally equipped and future-proof without limitations.

„With the FINEPLACER® coreplus so far I’ve never had to discard an assembly. And the machine is still running smoothly. I also like the compact and mobile design. Small for the win!“

Production THT