Chiplets and heterogeneous integration are shaping real products across AI, data centers, photonics, advanced sensing, and automotive systems. The advantages are established: higher yields from smaller dies, cost-optimized process nodes, and faster product updates by refreshing only the dies that matter. Just as important, system-in-package architectures bring logic, memory, RF, photonics, power, and sensors together in one tightly integrated module.

As architectures diversify, manufacturing challenges move upstream. Performance only materializes if these dies, often built with different processes and materials, can be placed, aligned, bonded, and scaled with exceptional precision. The message from the factory floor continues to grow louder: packaging is now where performance is won or lost.

A New Set of Manufacturing Realities

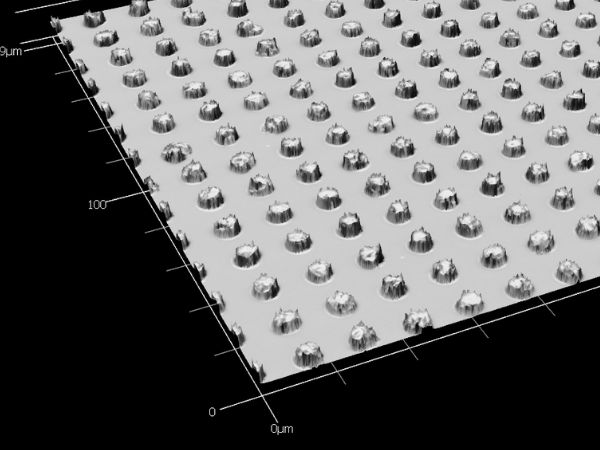

Engineering teams face tolerances and production pressures that were rare just a few years ago. Sub-micron placement is routine, hybrid bonding is entering production, and optical I/O demands alignment measured in fractions of a micron. Meanwhile, dies are thinning, III-V materials are more common, and thermal density rises in 2.5D and 3D stacks.

Product cycles are also tightening. Teams must move from concept to pilot to full production with fewer learning loops, while protecting proprietary processes and managing cost. The traditional separation between R&D and manufacturing no longer fits this environment. Precision and repeatability must be locked in during prototyping and carried into volume production without reinvention.

Success depends not only on designing the best dies, but on assembling them reliably, repeatably, and at scale.

What the Industry Now Needs

Organizations leading this transition build packaging capability early, maintain process continuity, and avoid resetting development at each stage. That requires tools and partners that provide:

- Verified sub-micron accuracy and in-process metrology

- Optical-grade alignment for photonic and high-speed I/O devices

- Adaptive handling for thin silicon, III-V wafers, and fragile assemblies

- Modular platforms spanning R&D, pilot, and automated production

- Close engineering collaboration and rapid process iteration

Flexible precision today, scalable automation tomorrow, and one process foundation throughout.

Where Finetech Fits In

Finetech supports this shift with a unified die-bonding platform from first prototype through volume production. Our systems combine sub-micron placement, optical alignment, and adaptive handling, all built on a unified platform architecture that spans from R&D to volume production. This consistency allows teams to develop faster, safeguard process knowledge, and ramp with confidence. With hands-on engineering support and collaborative development, customers gain precision and momentum from concept to established production.

The Bottom Line

Heterogeneous integration is redefining system design. Winning organizations treat packaging as strategic, embrace precision early, and scale without compromising process continuity. The future is multi-die, multi-material, and increasingly optical. Precision and scalability are now competitive advantage. Let us build that future and make it manufacturable.