Author: N.N.

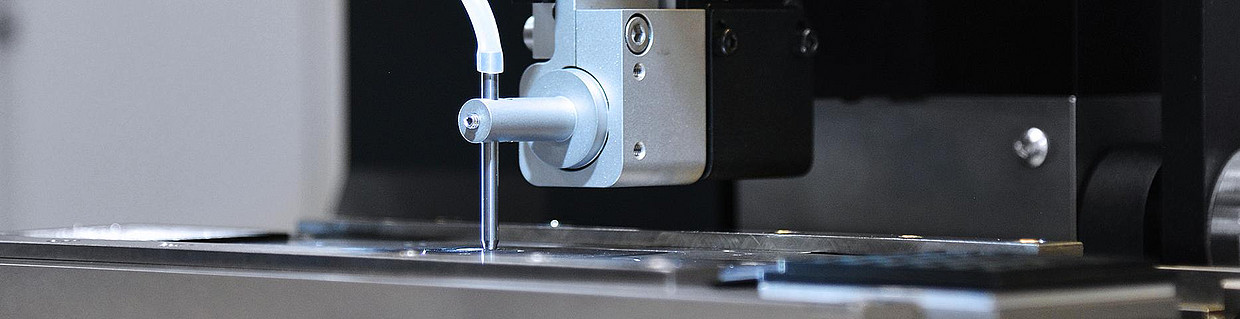

Abstract: Ultrasonic bonding is a process primarily used for flip chip bonding and allows to generate a mechanically and electrically stable connection. It is a friction welding process to attach a chip to a substrate without additional joining material. For this, both chip and substrate need metallized surfaces. In most cases, those surfaces are equipped with so-called bumps generated in a chemical process or by using a wire bonder. The bumps help reduce the contact area and compensate potential tolerances. Applying pressure (bond force) and ultrasonic energy initiate diffusion processes between the contact areas, establishing a solid connection. The actual process only takes several milliseconds. If additional heat from below is introduced into the process, it is called thermosonic bonding.

Ultrasonic die bonding is used for applications which have restrictions in terms of heat input or if is not possible to use joining partners like solder or adhesive (e.g. RF technologies). This technical paper describes the challenges of ultrasonic die bonding this packaging technology and gives an introduction to the possibilities Finetech provides to implement this packaging technology.

Document currently not available

We're on it. The document will be available soon.

For urgent questions, get in touch with the author.