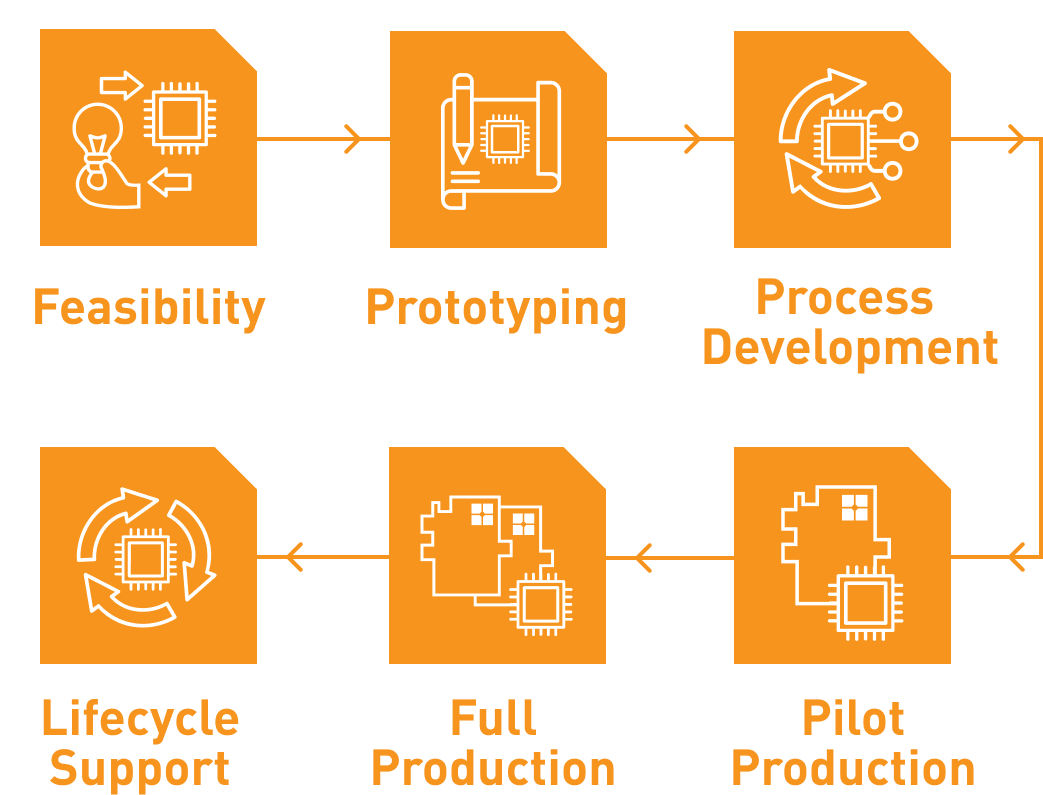

From feasibility to production –

full-lifecycle die bonding solutions

Finetech supports the entire die bonding lifecycle – from early feasibility and proof-of-concept to process optimization and scalable production workflows that maintain accuracy, yield and reliability.

Validate bonding strategies early to reduce risk and uncertainty.

Build stable, repeatable processes.

Use the same hardware platform and software environment from R&D to production. Scale your assembly as demand grows while keeping full accuracy.

From R&D to production, every stage keeps the same alignment accuracy and bonding behavior. A unified hardware and software platform avoids process drift, speeds up learning and makes scaling easy.

Validate Feasibility Early – Reduce Risk, Accelerate Development

Next-generation devices need bonding strategies tailored to your materials, architecture and device concepts. Start testing and iterating early to avoid costly dead ends.

» Define the right bonding strategy for your technology

» Run flexible trials without risking production resources

» Create functional samples quickly for proof-of-concept trials

» Define the right bonding strategy for your technology

» Run flexible trials without risking production resources

» Create functional samples quickly for proof-of-concept trials

Optimize your Process in Every Detail

Once your bonding approach is validated, the focus shifts to building stable, repeatable assembly recipes. Our intuitive software with clear parameter views and a proven recipe library makes refinement straightforward. Extensive customization capabilities at hardware and software level ensure tailored processes that perform consistently all the way into full production.

» Get full access and a clear view of all process steps

» No-code adjustment of process and machine parameters

» Optimize the process end to end according to your application requirements

» Get full access and a clear view of all process steps

» No-code adjustment of process and machine parameters

» Optimize the process end to end according to your application requirements

Scale Your Assembly as Demand Grows

Moving into production means equipping your team with qualified processes that deliver consistent output and high yield. Our flexible die bonders let you scale smoothly and give you the freedom to switch quickly between applications.

» Transfer validated processes into production without extra development loops

» Scale to higher volumes while maintaining process control and accuracy

» Shift quickly between different production tasks

» Transfer validated processes into production without extra development loops

» Scale to higher volumes while maintaining process control and accuracy

» Shift quickly between different production tasks

Long-Term Support Built In

Finetech supports your production across the entire system lifecycle, so your line stays reliable, adaptable, and ready for what comes next. With continuous process optimization, upgrades, service, and application support, your performance evolves with your requirements.

» Use modular upgrades to match higher volumes and changing needs

» Add new technologies without replacing your system

» Stay future-ready with continuous support

» Use modular upgrades to match higher volumes and changing needs

» Add new technologies without replacing your system

» Stay future-ready with continuous support