Based in Enschede, Netherlands, PHIX Photonics Assembly is a world leader in innovating photonic integrated circuit (PIC) assembly and manufacturing. Their goal is straightforward yet ambitious: setting new standards in the photonics industry.

Photonic integrated circuits (PICs) are chips in which photons are the carriers of data and energy. Compared to electronic integrated circuits (ICs), they can provide further miniaturization, higher processing speeds and lower power consumption. Also known as ASPICs, for application-specific photonic integrated circuits, these photonic chips have applications in key markets such as LiDAR, highspeed wireless data networks, medical devices, and quantum computing.

To make a PIC become a part of a functional photonics-enabled module, it needs to be connected to components like optical fibers, other PICs, cooling solutions, and electronics. The design and manufacturing of the package in which these connections are made is the core business of PHIX making it the photonic equivalent of an OSAT (Outsourced Semiconductor Assembly and Test) company.

PHIX offers a full range of services from design to high-volume manufacturing of PIC enabled modules, covering various material platforms. They specialize in hybrid integration, including chip-to-chip and fiber-to-chip connections, providing key services such as die bonding, wire bonding, and rigorous testing.

This extensive expertise positions PHIX as a comprehensive solution provider for clients aiming to move from prototype to mass production while ensuring the protection of intellectual property.

Sub-micron Accuracy for the Assembly of PIC and MEMS-based Modules

The manufacturing of PIC and MEMS-based modules is intricate, demanding precision in every single process step. PHIX’s capability to connect PICs with unmatched accuracy underlines their leadership in outsourced as well as contract manufacturing services in the photonic packaging domain.

Transitioning from a PIC to a functional module and from a first prototype to optimized designs ready for high-volume production entails a multi-disciplinary design process that incorporates product and assembly process design, along with equipment management.

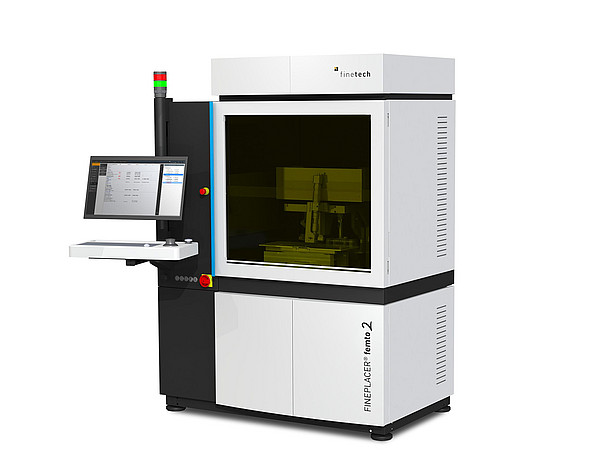

Speaking of equipment, a key element in PHIX’s assembly and manufacturing capabilities is the FINEPLACER® femto 2, Finetech’s cutting-edge automated sub-micron automated die bonder which PHIX has acquired in 2021.

This micro assembly cell, shielded from external influences, ensures stable assembly processes crucial for rapid prototyping and high-yield production. Its features, including the innovative FPXvision™ Vision Alignment System and IPM Command software, provide unparalleled flexibility and accuracy in PIC assembly.

The modular design of FINEPLACER® femto 2 allows for customization and easy retrofitting to accommodate new applications and technologies, making it a reliable tool for transitioning projects from development to production.

At PHIX, the FINEPLACER® femto 2 is used for a wide range of flip chip and die packaging tasks. This includes securing bare dies to a submount, vertically integrating PICs of different materials, and assembling components such as VCSELs, TIAs, ASICs, or photodiodes to the PIC.

Covered bonding methods include thermocompression bonding, soldering and adhesive bonding.

Photo-SENS

The FINEPLACER® femto 2’s significance is best exemplified in PHIX’ Photo-SENS project.

For the assembly of hybrid biosensor PICs, the advanced flip chip die bonder is used for the integration of optoelectronic parts like VCSELs, photodiodes (PD), and NTC thermistors on the PIC.

The FINEPLACER® femto 2 utilizes machine vision for the very accurate and fast placement and bonding of photonic components on the silicon substrate. This sub-micron accuracy alignment of electrical and optical interfaces is vital for the functionality and reliability of these sensors.

The localized heat for the gold-to-gold thermal-compression bond is applied using a custom laser source, which eliminates the need to reheat the entire wafer for each component. This enhances the efficiency and accuracy of PD arrays integration, while mitigating irregular bonds due to high temperature duty cycles or long annealing periods, and allows PHIX to perform bonding of VCSELs, photodiode arrays, and thermistors onto a silicon nitride platform at the wafer level.

Using the FINEPLACER® femto 2, PHIX can provide scalable manufacturing processes for photonic biosensors with applications in medical diagnostics, agriculture-food, and environmental monitoring.