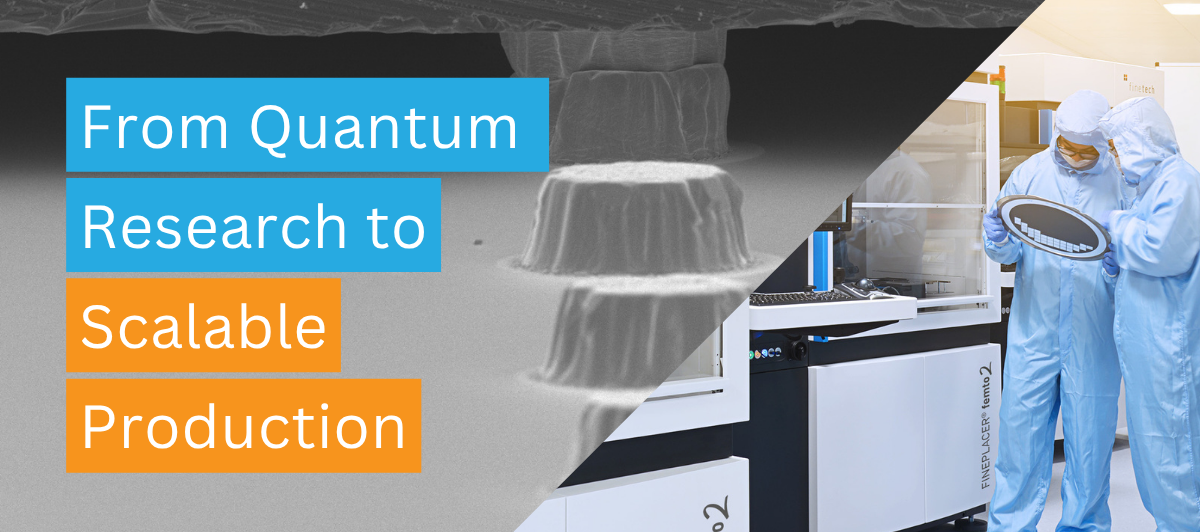

Quantum technology is quickly shifting from experimental research to commercial impact. In 2025, real-world demand for scalable, high-precision quantum hardware is growing fast.

According to McKinsey’s >Quantum Technology Monitor:

- Quantum computing revenues will surpass $1B in 2025

- Investment is accelerating across venture and public sectors

- AI and quantum are converging, driving innovation

- Security and manufacturability are becoming top priorities

- By 2035, quantum could unlock $97B in revenue and up to $2T in industry value

Scaling this technology requires new levels of bonding precision, reliability, and packaging flexibility.

The Integration Challenge

As quantum devices move toward production, manufacturers face unique die bonding challenges:

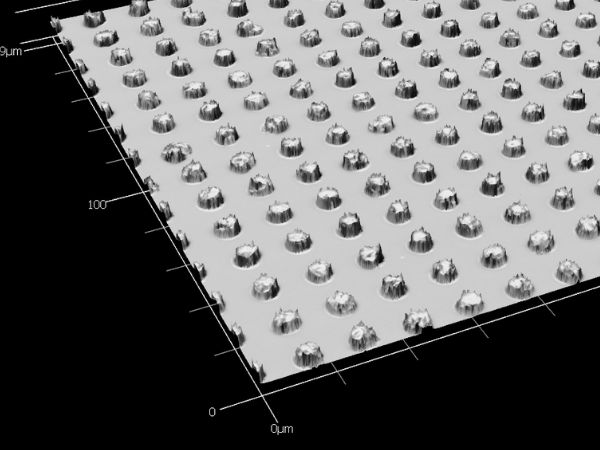

- Fragile chips and photonic devices require sub-micron bonding

- Cryogenic-compatible interconnects, such as Indium bumps, demand exact process control

- Integration of optics, RF, and electronics must be compact and defect-free

Off-the-shelf tools aren’t enough—next-gen quantum hardware needs advanced, adaptable platforms.

Customer Success: Superconducting Qubits at WMI

The Walther-Meißner Institute (WMI) is developing superconducting quantum processors with over 100 qubits. This requires ultra-precise Indium bump bonding, tight planarity, and scalable, reproducible processes.

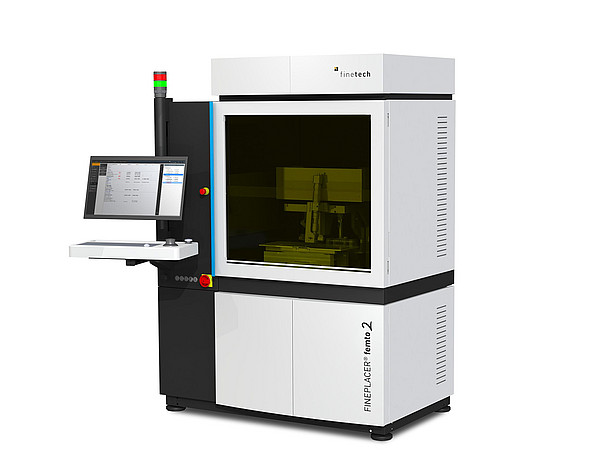

To meet these demands, WMI chose Finetech’s >FINEPLACER® femto 2 after extensive trials using their own samples. The system delivered:

- Reliable sub-micron Indium bump bonding with cold compression

- Repeatable, clean processes for low-volume, high-value quantum devices

- A modular platform that scales with evolving integration needs

- Local technical support and direct collaboration with Finetech engineers

This partnership helped WMI move from research trials to real manufacturing readiness — and set the foundation for future scaling into chip stacking and fan-out packaging.

Why Finetech?

Finetech helps quantum innovators scale confidently, from prototype to production:

- Placement accuracy down to 0.3 µm @ 3 Sigma

- Flexible bonding processes: thermocompression, eutectic, Indium, laser-assisted, and more

- One platform from prototyping through volume production

- Over 30 years of experience in photonics, quantum, and cryogenic packaging

Whether you’re building photonic circuits, trapped-ion processors, or superconducting systems, Finetech delivers the tools and expertise to scale precision bonding — every step of the way.

Let’s Build Quantum Together

Quantum technology is advancing fast — and manufacturing must keep pace. At Finetech, we go beyond equipment, offering expert support and precision solutions tailored to quantum’s unique challenges.

Let’s turn quantum potential into production-ready reality.