Productronica 2023:

Advanced SMD Rework Solutions at Booth A4.181!

+++ We would like to thank our many visitors, familiar and new faces, with whom we had many great conversations. We are already incredibly excited to be working with you to bring your product visions to life! +++

Hot gas rework systems for advanced rework challenges. For reliable, good-as-new reworked components.

With reliable rework solutions, you reduce scrap in electronics production, make yourself less dependent on uncertain supply chains, and set up your company to be more resource-efficient and sustainable.

Finetech advanced rework systems based on hot air technology target professional rework of electronic components and modules according to IPC/JEDEC standards. The entire rework cycle can be implemented on the same machine.

Our hot gas rework systems support the whole range of commercially available SMD components – from very small designs (008004) to massive BGAs. Any challenge can be tackled with utmost precision and control of process parameters.

Finetech can support you in SMD rework tasks where the highest quality and reliability of the reworked assemblies are paramount.

+++ We would like to thank our many visitors, familiar and new faces, with whom we had many great conversations. We are already incredibly excited to be working with you to bring your product visions to life! +++

Hot gas rework systems for advanced rework challenges. For reliable, good-as-new reworked components.

With reliable rework solutions, you reduce scrap in electronics production, make yourself less dependent on uncertain supply chains, and set up your company to be more resource-efficient and sustainable.

Finetech advanced rework systems based on hot air technology target professional rework of electronic components and modules according to IPC/JEDEC standards. The entire rework cycle can be implemented on the same machine.

Our hot gas rework systems support the whole range of commercially available SMD components – from very small designs (008004) to massive BGAs. Any challenge can be tackled with utmost precision and control of process parameters.

Highlights

A major challenge in this type of rework is the size of the passive components, with increased demands on handling, placement accuracy and reproducibility.

Learn more about our complete small passives rework process including component re-alignment or removal, site cleaning and optional paste application and replacement, with real-time optical inspection during the process.

#SmallPassive #008004 #01005 #SolderRemoval #PasteApplication #ForceControl #ToolDesign #ThermalManagement

The demand for more functionalities and performance on smaller PCB continues the trend of miniaturized, increasingly complex devices with extreme packing density and a rising I/O count.

Get to know our "all-in-one" professional rework strategies for array packages.

#BGA #CSP #Reballing #SolderRemoval #SolderApplication #Underfill

Mini BGAs are also often found near very heat-sensitive components, such as optical components on transceiver modules. Here, it is particularly important during rework that the critical temperature is not exceeded by using optimized tooling and process solutions in order to prevent damage.

Get to know our solution for mini BGA rework.

So why don't you bring your most difficult rework task currently to Productronica 2023 and put our rework system to the test.

Thanks to the sophisticated temperature management and process solutions of the FINEPLACER® core plus, we are confident that we can show you in Munich the way to a reliable, good-as-new repair of your PCB or component.

Book an appointment in advance and allow us to give you the best possible consultation on your individual application challenge.

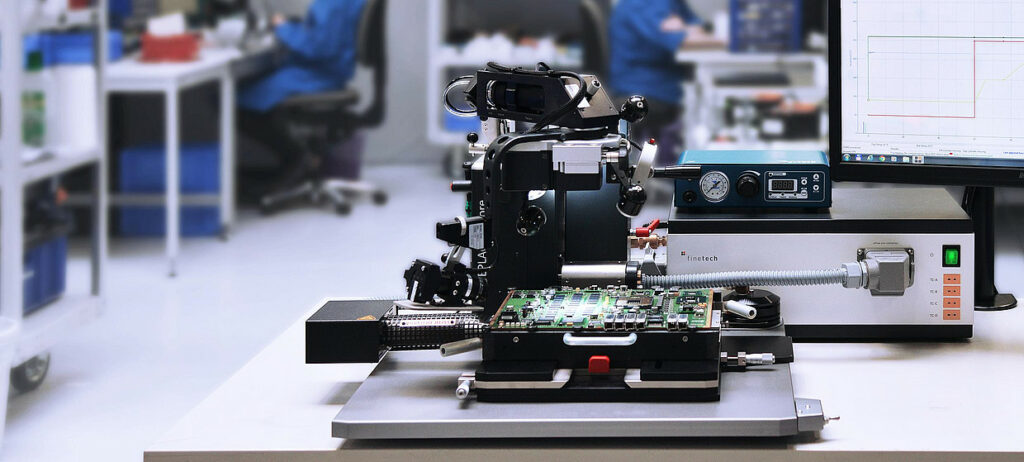

FINEPLACER® core plus

Our universal hot air rework station for electronic components and assemblies.

Numerous professional features, such as digital top heater calibration, precision touchdown force control and live process observation, make the FINEPLACER® coreplus a future-proof investment when the demands get tougher.

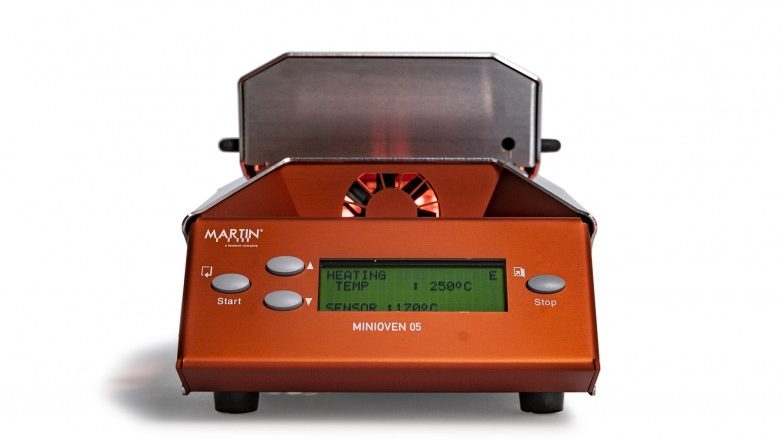

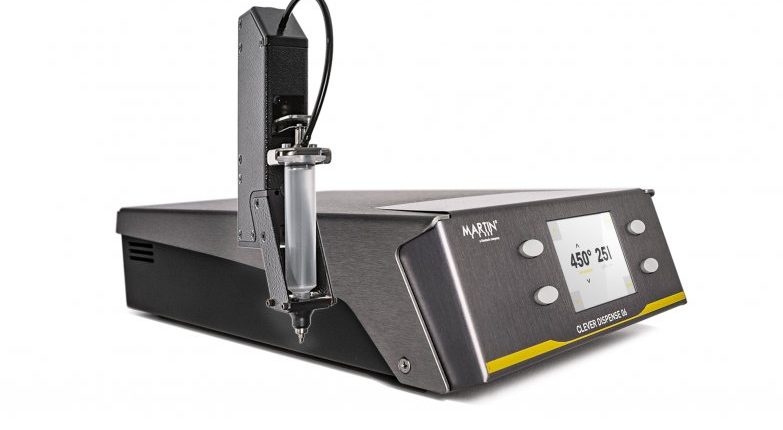

MARTIN Rework & Dispensing Solutions

Fast. Precise. Reliable

MARTIN, a Finetech company, is a globally active German equipment supplier in the field of special mechanical engineering.

MARTIN has been developing SMD rework and dispenser systems for customers from various industries. They offer precise, fast, handy and intuitive devices for all necessary work steps.

Today, the company has over 30 years of experience in rework and dispensing technology. More than 3,000 installed devices worldwide ensure smooth and economical production processes.

MARTIN

Fast. Precise. Reliable

MARTIN, a Finetech company, is a globally active company in the field of special mechanical engineering.

For many years MARTIN has been developing REWORK and DISPENSE systems for customers from various industries. Their offer precise, fast, handy and intuitive devices for all necessary work steps. Their product range is divided into two areas: REWORK and DISPENSE.

Tradeshow impressions

Why Finetech?

✓ Expertise in SMD rework: Our track record is not just 30+ years of experience; it’s excellence. Your challenge become our challenge, and we love it when it gets really demanding.

✓ Unwavering reliability: What our machines rework comes out as good as new: that’s our commitment. Discover solutions that bring valuable components back to life, ensuring that reworked items are as reliable as the originals.

✓ Quality assurance: Quality is not a promise, it’s a guarantee. When you work with us, you are assured of the highest quality SMD rework processes. Your satisfaction is our unwavering pursuit.

✓ Advanced technology: Our rework systems, based on advanced hot gas technology, cover the entire range of SMD components. From super small to massive, we can do it all.